HORIZON

The Horizon robot guide vision system is able to work with the following types of cameras:

KEYENCE

We also use the Keyence vision system for both robot guidance and quality control applications.

![]()

In both systems, image processing is used to reduce the influence of ambient light.

It is possible to use several cameras at the same time, the acquisition speed depends on the type and resolution of the camera.

The system includes an image preprocessing phase in order to reduce noise and increase its quality.

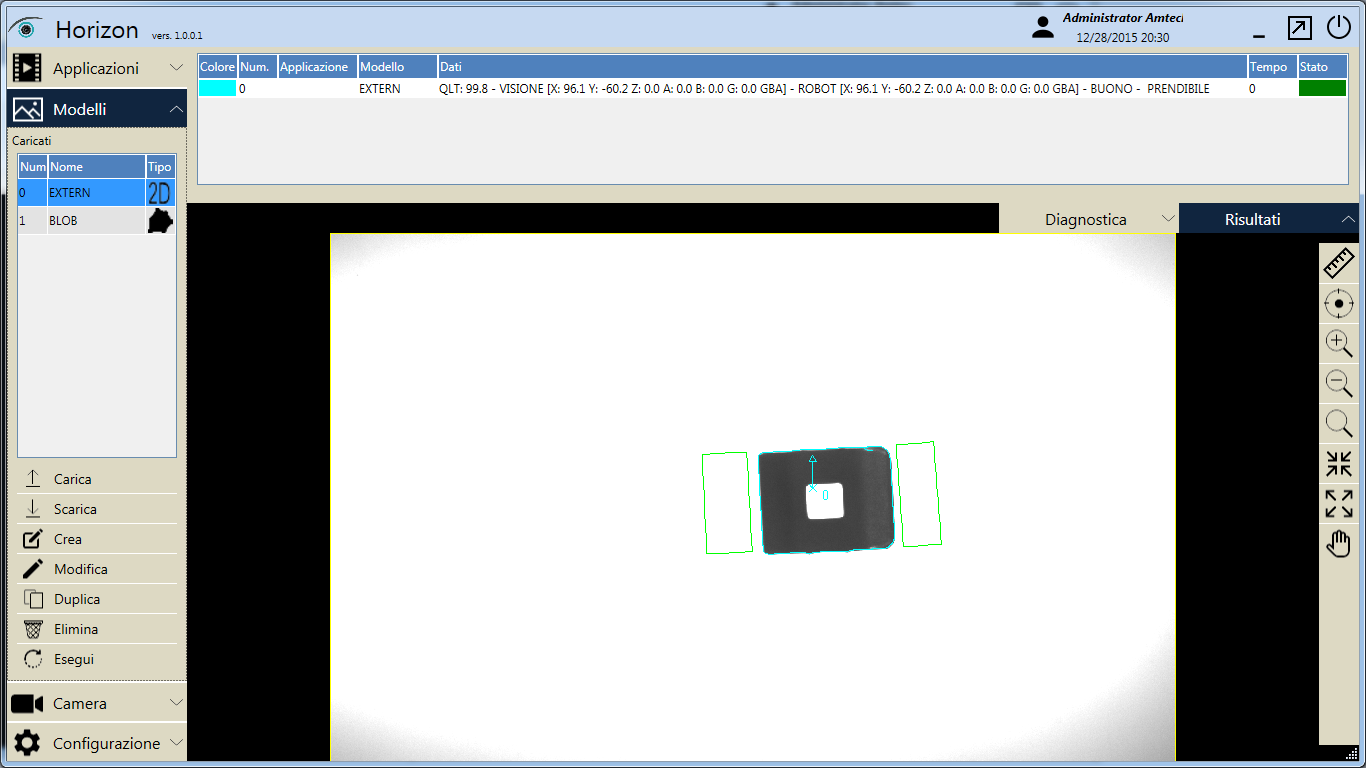

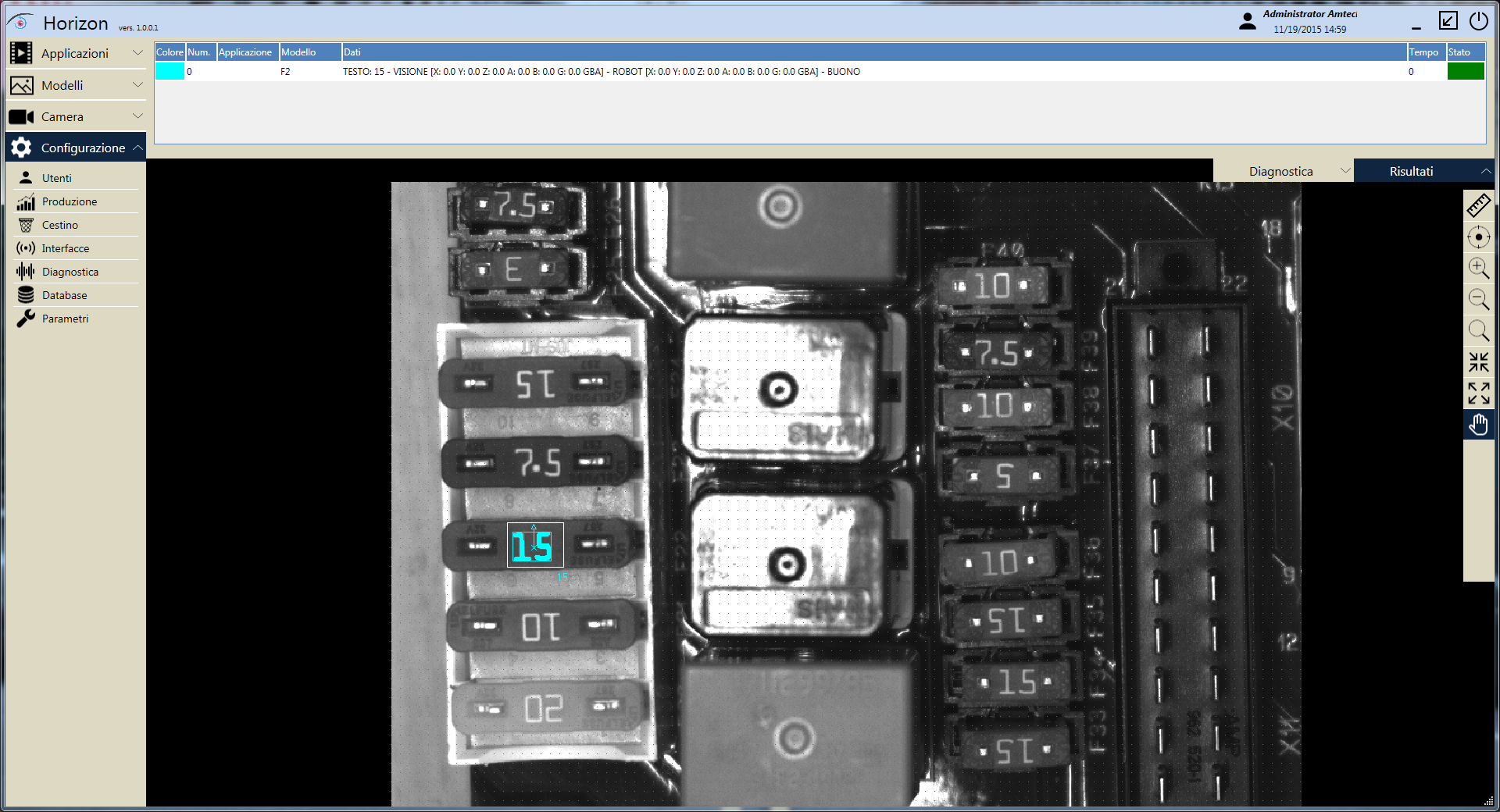

Example 1: Profile reconstruction

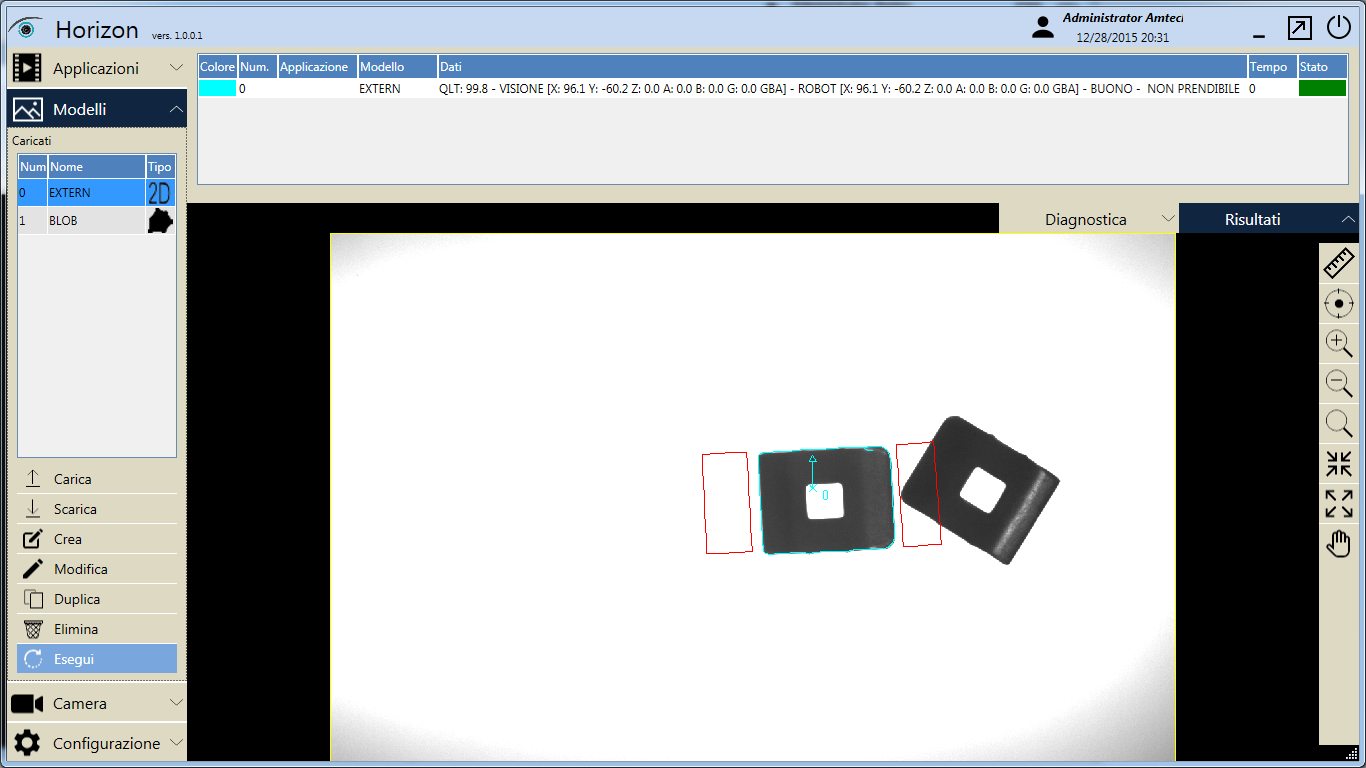

The model is associated with the workpiece gripping areas.

In the image below, one of the two areas is occupied by a piece and the system identifies the piece as not pickable.

In addition it is also possible to use the processing of color spots for the identifications of particular consist of simple geometric shapes or devoid of shape constraints, such as for example foods such as fruits or vegetables.

The system is able to recognize and decode the following types of 1D/2D codes:

- Barcode

- Datamatrix ECC 200

- QR code

- Micro QR code

- Aztec code

- PDF 417

Within the same framed area there may be multiple codes that the system distinguishes both by type and by position, and decodes correctly.

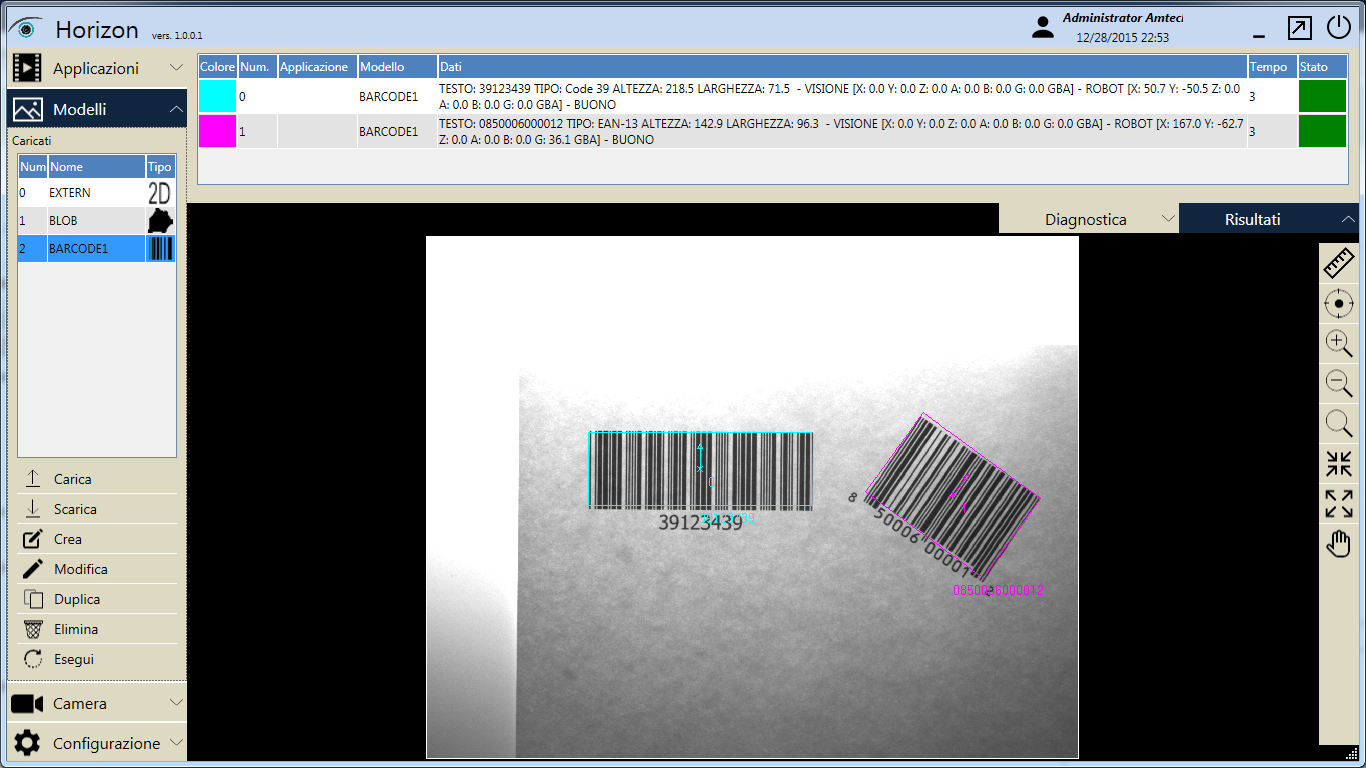

Example 1: Barcode decoding

In this example, the system recognizes the presence of two objects with different encoding, position, rotation angle.

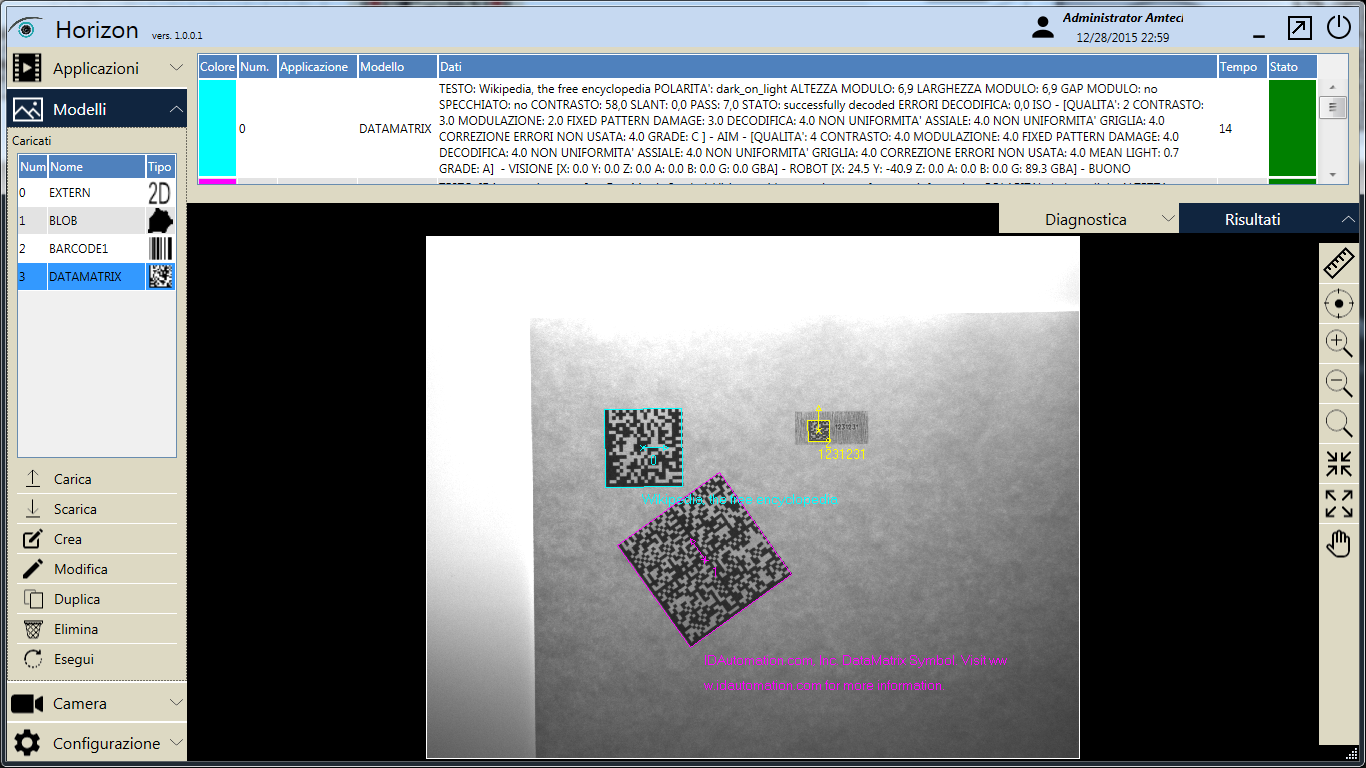

Example 2: Datamatrix decoding

The 2D code decoding capacity also extends to codes made by laser or with punching machine, the system can guarantee a correct decoding even in the most extreme cases.

The system is able to provide the classification of the reading degree according to various standards for:

- Datamatrix ECC 200

- QR code

- Micro QR code

- Aztec code

- PDF 417

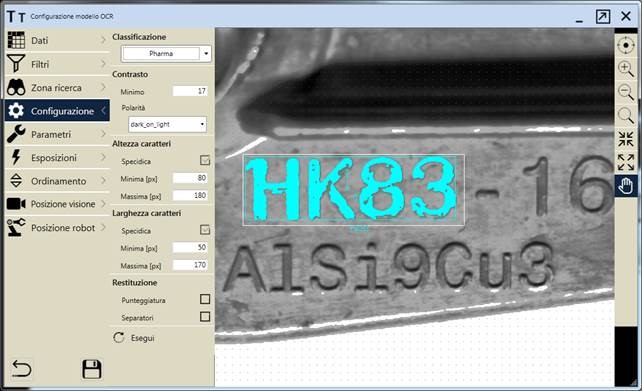

The system is able to correctly recognize and decode the character sequences in the following cases:

- Printed labels

- Screen printing on the piece

- Laser marking

- Micro dot marking

- Embossed characters

It is possible to identify:

- the position of the writing

- its orientation on X-axis

- the size of the individual characters

- the contents of the string

The result of the decoding is a sequence of characters in ASCII encoding that the system has identified.

Examples: